Priority-Based Planning

Topic: - Introduction to Priority-based planning in

Dynamics 365 F&O.

Pre-requisites: -

1. Before

you install the Planning Optimization Add-in, the following prerequisites must

be in place:

·

You must be running Supply Chain

Management on an LCS-enabled high-availability environment, tier 2 or higher

(not a OneBox environment), with Dynamics 365 Supply Chain Management version

10.0.7 or later. If you try to install the add-in on a OneBox environment, the

installation will not complete, and you will need to cancel the installation.

·

Your system must be set up for

Power Platform integration.

2.

Enable the Planning Optimization

license

3.

Install the Planning Optimization Add-in

4.

Integrate Planning Optimization

with your system

5.

Connection status

6.

The Use Planning Optimization

option

7.

Integration with the setup

Agenda: -

1.

What

is Priority-based planning?

2. Benefits

of priority-based planning

3.

With

priority-based planning, organizations gain the capability to

4.

Where

and how planning priorities are assigned

5.

Types

of priority calculation methods

6.

Pre-requisite

7.

Business

scenarios

1.

What is priority-based planning?

Priority-based planning can help businesses optimize their

supply chain while increasing service levels and reducing inventory levels. Priority-based

planning enables Planning Optimization to generate planned orders that are

driven by planning priorities instead of requirement dates.

2.

Benefits of priority-based planning:

-

· This

feature adds support for demand-driven planning, which is one of the five steps

related to demand-driven material requirements planning (DDMRP). With

priority-based planning, the optimization of supply to cover demand is based on

priorities, not requirement dates, which are used in classic material

requirements planning (MRP).

·

Priority-based planning lets you prioritize

replenishment orders to ensure that urgent demand is prioritized over less

important demand. For example, a stockout replenishment order will be

prioritized over a standard refill replenishment order. The system can

automatically split larger orders into separate smaller orders where order

lines are grouped by priority. It can then process all high-priority orders

first.

·

On top of this, the system can automatically

split large refill orders into separate, smaller orders, with different

priorities assigned to each order. This approach provides coverage of the

critical portion of an inventory refill, instead of simply refilling warehouses

to the maximum with a single supply. This minimizes the risk of stockout by

optimizing the use of available supply.

·

Another benefit of priority-based planning is

that priority can be used to compare the importance of relevant orders across

products and locations during execution planning.

3.

With priority-based planning,

organizations gain the capability to: -

· Calculate,

manually edit, or default on planning priorities.

· Control

replenishment by setting reorder point parameters.

· Split

and optimize distribution orders using planning ranges.

· Group

planned orders at firming.

· Utilize

customizable planning priority ranges.

· Apply

planning priority capabilities to intercompany orders.

4.

Where and how planning priorities are

assigned?

Planning priority information about supply and

demand is the backbone of priority-based planning. Planning priority defines

the importance of a demand or supply line. Planning optimization uses it when

the coverage code field is set to priority.

The planning priority is usually a number between 0

(zero) and 100, where 0 represents the highest importance. It is shown and set

in the Planning priority field. You can find this field on the

following pages

a)

Demand forecast lines

b)

Sales order details

c)

Purchase order details

d)

Transfer order details

e)

Planned order details

When

the coverage code field for the relevant item or coverage group is

set to Priority, planning optimization balances supply with demand by

using a demand-driven approach as it calculates the planning priority and, for

each released product, considers the values that are set for the minimum, reorder

point, and maximum fields on the item coverage page.

5.

Types of priority calculation methods

Each planning priority model has a priority

calculation method setting that controls how master planning applies

priority to planned orders. The available values are Percent of maximum

inventory quantity and Priority ranges. Priority ranges represent

a more advanced version of the Percent of maximum inventory

quantity method.

· Percent of maximum

inventory quantity: -

In the percent of maximum inventory

quantity calculation method, the supply priority calculation finds the

current total available inventory (net flow) as a percentage of the maximum

inventory quantity value that is set for an item. A single planned order

is then created per item and vendor (unless the maximum order quantity is used

to force a split). The planning priority of the order is calculated as a

percentage of the maximum.

The following formula is used:

Percentage of maximum = (Net flow

position × 100) ÷ Maximum inventory quantity value from the item

coverage

In this formula, the net flow position is

calculated in the following way:

Net flow

position = On-hand + On-order – Qualified demand

On-order is the expected supply.

Qualified demand represents the net requirements

that have the requirement date within the planning time fence.

During the master planning run, new planned orders are

created when the net flow position is less than the reorder point quantity for

an item. The planned order quantity is the difference between the maximum

inventory quantity value that is set at the item level and the net flow

position. The planned order priority is calculated as a net flow

position percentage of the maximum inventory quantity value.

· Priority ranges: -

The priority ranges calculation method is

more advanced than the percent of maximum inventory quantity method

and is configured at the level of the planning priority model. Several new

planned supply orders can be created to fulfil the demand per item. The

priorities of the planned supply follow the values that are defined in

the planning priority ranges grid on the Planning priority

models page.

The following additional rules become effective when

the priority calculation method field is set to Priority ranges:

§

If the considered demand priority option for the

planned priority model is set to Yes, a priority that is set on each demand

line will limit the priority range bucket. The priority of any new planned

order for supply will be no lower than the demand's priority. The range's upper

value is considered a threshold that the demand's priority value compared. If

the demand's priority is exactly in the middle between the upper threshold

values of two ranges, the range that has the highest priority (that is, the

lowest priority value) will be selected.

§

If the planned order creation field for the

planned priority model is set to a Single supply with the most important

priority, only one supply will be created to fulfil up to the maximum. The

priority will be set to the priority of the first range that will trigger a

supply.

§

If there is no on-hand inventory, no supply, and

no demand, the line in the Planning priority ranges grid, where the from

quantity field is set to Zero, will be used.

§

If there is demand, but there is no on-hand

inventory or expected supply, the line in the Planning priority ranges grid,

where the from quantity field is set to Zero or less, will be used.

§

When the range that the demand is part of is

evaluated, the setting of the Consider demand priority option will still have

an effect.

6.

Pre-requisites: -

· We

need to enable the “Planning Optimization” functionality within the feature

management.

· In

Feature management, turn on “(Preview) Priority driven MRP support for Planning

Optimization.”

· Set up your first

planning priority model: -

Planning priority models are assigned to

coverage groups and control the planning priority for planned orders. They

define the logic that determines how the planning priority value is calculated

for each planned order, and how priority is assigned to planned orders, supply

lines, and demand lines.

To work with the planning priority models, go

to Master planning > Setup > Planning priority models. As was

previously discussed, one of a model's most important settings is the priority

calculation method value. This setting controls the calculation used when

master planning assigns a priority value to planned orders.

· Coverage Group: -Set

up a coverage group that includes your planning priority model.

·

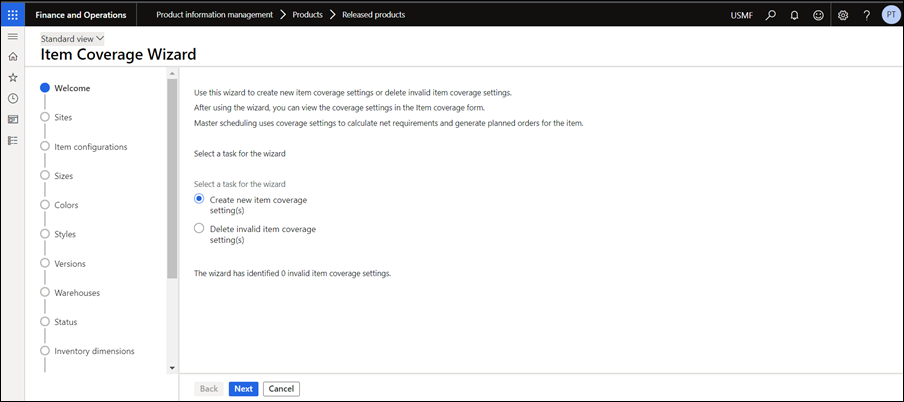

Item Coverage: -Set up item coverage

for items with the newly created coverage groups as needed to drive the

minimum/maximum values and new reorder point values to trigger the planned

order during the Master Plan run. The reorder point creates an opportunity to

use the minimum value as a true safety stock value to ensure less opportunity

for stock out in future business.

When sales orders, transfers,

purchase orders, and demand forecasts are created, the planning priority field

will generate automatically per the defaults set in the planning priority

model. These default values can be overridden within the order line details.

Master planning will generate new planned purchase orders, demand forecasts,

and transfer order suggestions when the projected on-hand value falls below the

reorder point. The value and number of planned orders will be determined by the

planning priority model and item coverage of the released product. In standard

D365 operation, net requirements will update once master planning has been run

again. Within net requirements, the planner can see a new column with the

calculated planning priority. The planning priority value provides the planner

with an additional data point when allocating current inventory, and existing

or future supply-to-demand orders.

Run master planning and try out

the planning priority model setup to see the impact of the calculated planning

priority on planned orders.

7.

Business scenarios: -

·

Scenario 1 for the maximum priority

percentage: -

For

the item, Mouse11 warehouse W001 is the main central warehouse, and it has W002,

and W003 two local warehouses replenished by central warehouses (W001). W001 the

minimum quantity of 10 (safety stock) is then added to get a reorder point of 50

and the maximum quantity is 100. When this setup is used, supply will be

suggested when the projected on-hand level is below 50. The order priority will

be based on the planning priority setup.

The

maximum inventory level for an item in local warehouse W002 is 80 pieces, the

minimum inventory qty is 10 pieces and the reorder point is 35. the projected

on-hand inventory is 50 and therefore gets assigned a priority of (20/80)

*100=25. In another local warehouse, W003 is 70 pieces, and the reorder point

is 30, the projected on-hand inventory is 15 and therefore gets assigned a

priority of (15/70) *100=21.43. The warehouse W003 is considered at a higher

risk of stock-out and gets replenished before the warehouse in W002.

Item coverage group table

|

Warehouse |

Minimum |

Reorder Point |

Maximum |

On hand |

|

W001 |

10 |

50 |

100 |

100 |

|

W002 |

10 |

35 |

80 |

20 |

|

W003 |

10 |

30 |

70 |

15 |

According

to the above table, W002 requires 60 pieces and W003 55 pieces from the central

warehouse W001. Warehouse W001 has 100 pieces in the warehouse but to

fulfilling the local warehouses and their own need central warehouse will

create planned purchase order of 115 pieces.

Net requirement

table

|

Warehouse |

Planned order type |

Required Qty |

Planning priority Percentages |

|

W001 |

Purchase |

115 |

0 % |

|

W003 |

Transfer |

55 |

21.43% |

|

W002 |

Transfer |

60 |

25% |

Planning

priority percentages are calculated based on a project on hand qty.

·

Scenario 2 for the priority ranges

for single planned order creation type:

For

the item, Mouse12 warehouse W001 is the main central warehouse, and it has

W002, and W003 two local warehouses replenished by central warehouses (W001).

W001 the minimum value of 10 (safety stock) is then added to get a reorder

point of 50 and the maximum quantity is 100. When priority ranges setup is

used, supply will be suggested when the projected on-hand level is in between

priority ranges. The order priority will be based on the planning priority

setup.

The

maximum inventory level for an item in local warehouse W002 is 80 pieces, the

minimum inventory qty is 10 pieces and the reorder point is 35 pieces. the

projected on-hand inventory is 20 pieces according to the priority ranges set

up the project on-hand qty is between minimum inventory qty to reorder point

qty and therefore it gets assigned a priority of 50 %.

In another local warehouse,

W003 is a maximum inventory level of 70 pieces, a minimum is 10 pieces, and a

reorder point is 25, the projected on-hand inventory is 0 according to the

priority ranges set up for the project on hand qty between zero qty to minimum

order qty and therefore it gets assigned a priority of 30 %. The warehouse W003

is considered at a higher risk of stock-out and gets replenished before the

warehouse in W002.

Item coverage group

table

|

Warehouse |

Minimum |

Reorder Point |

Maximum |

On hand |

|

W001 |

10 |

50 |

100 |

100 |

|

W002 |

10 |

35 |

80 |

20 |

|

W003 |

10 |

25 |

70 |

0 |

According

to the above table, W002 requires 60 qty and W003 70 qty from the central

warehouse W001. Warehouse W001 has 100 qty in the warehouse but to fulfilling

the local warehouses and his own need central warehouse will create planned

purchase order of 130 qty

In the

central warehouse, W001 is a maximum level inventory of 100 pieces, and the

reorder point is 50, the projected on-hand inventory is below 0 according to

the priority ranges set up for the project on hand qty is between from zero qty

to zero or less qty and therefore it gets assigned a priority of 10 %.

Net requirement

table

|

Warehouse |

Planned order type |

Required Qty |

Planning priority Percentages |

|

W001 |

Purchase |

130 |

10 % |

|

W003 |

Transfer |

70 |

30% |

|

W002 |

Transfer |

60 |

50% |

·

Scenario 3 for the priority ranges

for split planned order creation type:

For

the item, Mouse13 warehouse W001 is the main central warehouse, and it has

W002, and W003 two local warehouses replenished by central warehouses (W001).

W001 the minimum value of 10 (safety stock) is then added to get a reorder

point of 50 and the maximum quantity is 100. When priority ranges setup is

used, supply will be suggested when the projected on-hand level is in between

priority ranges. The order priority will be based on the planning priority

setup.

The maximum inventory

level for an item in local warehouse W002 is 80 pieces, the minimum inventory

qty is 10 pieces and the reorder point is 35 pieces. the projected on-hand

inventory is 20 pieces it requires 15 pieces to match the reorder point

according to the priority ranges set up the project on hand qty is between from

minimum inventory qty to reorder point qty and therefore it gets assigned a

priority of 50 %. The match the maximum inventory of 80 pieces we require 45

pieces qty which is between, from reorder to maximum inventory priority range therefore

it gets assigned a priority of 70 %

In another local warehouse,

W003 is a maximum inventory level of 70 pieces, a minimum is 10 pieces, and a

reorder point is 25, the projected on-hand inventory is 0 pieces it requires 10

pieces to match the minimum inventory according to the priority ranges set up

the project on hand qty is between from zero qty to minimum qty and therefore

it gets assigned a priority of 30 %. To match the reorder point of 25 pieces we

require 15 pieces qty which is between, from minimum to reorder priority range therefore

it gets assigned a priority of 50 %. To match the maximum of 70 pieces we

require 45 pieces qty which is between, from reorder point to the maximum

inventory level priority range therefore it gets assigned a priority of 70 %

Item coverage group table

|

Warehouse |

Minimum |

Reorder Point |

Maximum |

On hand |

|

W001 |

10 |

50 |

100 |

100 |

|

W002 |

10 |

35 |

80 |

20 |

|

W003 |

10 |

25 |

70 |

0 |

According

to the above table, W002 requires 60 qty and W003 70 qty from the central

warehouse W001. Warehouse W001 has 100 qty in the warehouse but to fulfilling

the local warehouses and his own need central warehouse will create planned

purchase order of 130 qty

In the

central warehouse, W001 is a maximum level inventory of 100 pieces, and the

reorder point is 50.

·

To match the maximum qty 100 it will go in the first

range from reorder to max the max is 100 pieces and reorder point is 50 pieces (100-50=50)

the projected on-hand qty is 50 pieces, therefore it gets assigned a priority

of 70%.

·

The reorder point is 50. To match the reorder

point qty 50 it will go in the second range from minimum to reorder the reorder

is 50 pieces and the minimum is 10 pieces (50-10=40) the projected on-hand qty

is 40 pieces, therefore it gets assigned a priority of 50%.

·

To match the minimum qty 10 it will go in the third

range from zero to minimum the minimum is 10 pieces (10-0=10) the projected

on-hand qty is 40 pieces, therefore it gets assigned a priority of 30%.

·

The rest qty 30 pieces will go in the fourth

range from zero or less to zero the projected on-hand qty is 0 pieces,

therefore it gets assigned a priority of 10%.

Net requirement table

|

Warehouse |

Planned order type |

Required Qty |

Planning priority percentages |

|

W001 |

Purchase |

50 |

70 % |

|

|

Purchase |

40 |

50

% |

|

|

Purchase |

10 |

30 % |

|

|

Purchase |

30 |

10

% |

|

|

|

|

|

|

W002 |

Transfer |

15 |

50

% |

|

|

Transfer |

45 |

70 % |

|

|

|

|

|

|

W003 |

Transfer |

10 |

30% |

|

|

Transfer |

15 |

50% |

|

|

Transfer |

45 |

70 % |

No comments:

New comments are not allowed.