Landed

Cost Module

Topic:

Introduction

to the Landed Cost module in Dynamics 365 for supply chain management.

Agenda:

- 1.

What is a landed cost module?

- 2.

Module benefits

- 3.

Advantage

- 4. Landed cost concepts

- 5. Pre-requisite

- 6. End-to-end process

- 7. Business scenarios

- 8. Transfer orders

- 9. Landed cost vs. Transportation management

1.

What is a landed cost module?

The Landed cost module

helps businesses streamline inbound shipping operations by giving users

complete financial and logistical control over imported freight, from the

manufacturer to the warehouse.

Landed cost provides accurate and

timely cost estimates for overhead landed costs. At the same time, it provides

increased financial and logistical visibility into the extended supply chain.

It also helps reduce the administration of costing and costing errors.

2.

Module benefits: -

·

Improved visibility for tracking

inbound purchase orders and transfer orders

·

Ability to accurately track both

estimated and actual landed costs associated with inbound voyages.

·

Ability for companies to take legal ownership

of goods overseas and accrue item costs while in transit.

3.

Advantages: -

· Provide

More Accurate Information: - It

gives you an accurate calculation and helps you avoid unexpected

expenses.

·

Goods Tracking Information: - A complete

update on each step of transit. Lead time and shipment status are identified.

Users are allowed to change these delivery dates.

·

Helps to Reduce Expenses: - Look at all their expenses

related to the shipping items. Helps to reduce unnecessary costs and

make current costs worthwhile by increasing your profit margin.

4.

Landed cost concepts:

§

Voyages: A voyage is a distinct movement from an

outbound location, through a specific set of destinations over a specified

period, to a specified inbound warehouse location.

§ Folio: A folio is often determined by customs

regulations. It can consist of one vendor's goods for one entity/company per

shipment. The goods in a folio can be in one container or spread among multiple

containers.

§

Journey templets: -

Journey templets are routes that goods moved between two ports.

§

Port: Ports are areas where goods

are received and transferred from.

§

Vessel: A vessel is a

medium that is used to transport goods, such as a ship or an airplane.

§

Shipping container: A

shipping container is used to group goods that are either physically grouped or

have the requirements to share costs across these goods.

§

Activity: Activities

can be used to store each significant step of the journey between two ports.

They can be used to update estimated delivery dates.

§

Goods in transit: The

goods-in-transit refers to the merchandise and other inventory items that have

been shipped by the seller, but not yet received by the buyer.

§

Auto costs: Auto

costs work like a trade agreement. An auto cost is linked to a voyage level.

§

Cost type: Cost types identify costs that are associated with imports,

such as duty, freight, and insurance.

§ Over/under

transactions: - When the orders in a voyage are processed,

the system expects the item quantity that is received in the final destination

warehouse for consumption to match the quantity that is specified on the

purchase order lines that are associated with the voyage. However, because the

exact quantity on the purchase order lines isn't always received in the

warehouse, the Landed cost module defines a set of rules that are

used to handle the over-receiving and under-receiving of goods. These rules are

especially important because the original purchase order has been invoiced and

can no longer be modified. By setting up the details of over/under transaction

policies, you enable the system to determine how to manage the over-processing

and under-processing of goods at the time of receipt. You can also manually

manage over and under inventory by using the Over/under

transactions page.

¨ Over/under

tolerances

¨ Over/under reasons

¨ Item over/under tolerance

groups

¨ Vendor over/under tolerance

groups

· Process

over/under transactions

The Action Pane on the Over/under transactions page

provides the following commands for processing the transactions that are

selected on the page. Each command lets you choose how to process each

transaction.

¨

Create > Movement – Create and post a movement journal

for the selected transaction. For under transactions, a movement journal is

automatically created and posted for the difference between the expected and

actual received quantity. Select this command for over transactions if you want

the vendor to realize the cost difference.

¨

Create > Purchase order – Create a

purchase order for the difference between the expected and received a quantity

of the selected transaction. Select this command for over transactions if your

organization will realize the cost difference.

¨

Create > Transfer to destination – This command

applies only to transfer orders. Select it if you want to transfer the over or

under quantity to the destination warehouse.

¨

Create > Transfer to origin – This command

applies only to transfer orders. Select it if you want to transfer the over or

under quantity to the origin warehouse

5.

Pre-requisite:

·

We need to enable the “Landed cost” feature

within the feature management.

· Configurations:

-

¨ Vendor

setting added for landed cost

When you enable the Landed cost module,

several new fields are added to the existing Vendors page.

You use these fields to set up the vendors that you will use together with

Landed cost features.

To set the relevant fields, go to Procurement and

sourcing > Vendors > All vendors. Open an existing vendor, or create a new

vendor, and then select the Miscellaneous details FastTab.

All the new fields that the Landed cost module adds appear under the Voyages heading.

¨ Landed

cost parameters setup.

You use the landed cost parameters page

to set up general information and configuration settings that are used across

the landed cost module for posting, status updates,

number sequences, and behavior. The setup of parameters is shared across legal

entities and can be modified by an administrator.

To work with the parameters, go to Landed cost

> Setup > Landed cost parameters

¨ Voyage

status setup

On the voyage statuses page, you

establish the set of status values that users can assign to voyages. Users can

assign voyage status values to all levels of a voyage: voyage, shipping

container, folio, purchase order, and item (purchase lines and transfer order

lines). They are used for two purposes:

§

Inform the user about the status of the voyage,

shipping container, folio, purchase order, or item (purchase lines and transfer

order lines).

§

Limit the use of the cost area by preventing

modification or deletion.

To set up your voyage statuses, go to Landed

cost > Setup > Voyage statuses.

Each cost area has its own set and hierarchy of

voyage statuses. Therefore, on the voyage statuses page,

in the cost area field, you must first select the cost

area that you want to view or create voyage statuses for.

¨ Shipping

container setup

Shipping container types define the types of

shipping containers that are available for use during shipping and voyages.

To work with the shipping container types, go

to Landed cost > Containers set up > Shipping container types.

There, you can view, add, and remove records for your container types

¨ Delivery

information setup

Shipping ports identify where goods are being

shipped from and to. For each voyage, a "to" port and a

"from" port are defined, based on the journey that is selected for

the voyage vessel. Shipping ports are used to build the legs of a journey and

the voyage activities. They are typically defined by using the name of the city

and the country or region where the physical shipping port is located.

To work with shipping ports, go to Landed cost >

Delivery information setup > Shipping ports.

There, you can view, add, and remove records for your shipping ports.

¨ Multi-leg

journey setup

Ø Legs:

-

Legs are used to identify separate parts of a

journey. Each leg is built by selecting the "to" and "from"

shipping ports, and the transportation method that is used for that leg. Lead

times can be associated with each leg. Lead times can help track a shipment and

can also be used to calculate the estimated delivery date of the goods on a

voyage. Additionally, when a leg of a journey is completed, the status of the

voyage, shipping container, and associated purchase order lines can be updated

through the tracking control setup. Legs can be used by a single journey

template, or they can be reused by multiple journey templates. Container

loading, customs, and local transport are set up as legs, and a non-specific

shipping port is used for them.

To work with legs, go to Landed cost >

multi-leg journey setup > Legs. There, you can view, open, create, and

delete records for legs.

Ø Journey

Templates: -

A journey template defines the multi-leg

journey between two ports where goods travel during a voyage. The legs of the

journey are combined to identify the amount of time that will be required for

goods to travel from the vendor's point of origin to the final warehouse

destination. When the legs are put on the journey template in a specific order,

the lead times will identify the date of each leg and the status of the voyage,

container, and purchase lines for the voyage.

To work with journey templates, go to Landed

cost > multi-leg journey setup > Journey templates.

There, you can view, open, create, and delete journey templates.

¨ Shipping

information setup

Ø Description

of goods: -

Descriptions of goods help identify a voyage,

shipping container, or folio of goods, and the goods in it. You can select a

description of goods on the shipping container header or the folio header.

To work with descriptions of goods, go to Landed cost >

Shipping information setup > Description of goods.

There, you can view, open, create, and delete records for descriptions of

goods.

Ø Vessels:

-

A vessel is the unique name of a ship or vessel

that a shipping company or agency uses. When you create a voyage, you must

always either select or enter a vessel for it. If you often use the same

vessels, then you can make it faster and easier to create a new voyage by

creating a vessel record for each of them, thereby allowing users to select the

vessel from a list rather than enter the name or number manually each time.

To work with vessels, go to Landed cost >

Shipping information setup > Vessels. There, you can view,

open, create, and delete records for vessels.

Ø Exporters:

-

Each exporter record identifies a vendor or

exporter that can be defined as the vendor for a voyage. The exporter can be

associated with a voyage and used for reporting.

To work with exporters, go to Landed cost >

Shipping information setup > Exporters. There, you can view,

open, create, and delete records for exporters.

Ø Commodity

Codes: -

You use commodity codes to help with customs

identification and the calculation of duty rates for goods on a voyage. You can

select commodity codes on the Released products page.

To work with commodity codes, go to Landed cost >

Shipping information setup > Commodity codes.

There, you can view, open, create, and delete records for commodity codes.

Ø Customs

Description: -

Customs descriptions help identify goods for

customs purposes. You can select a custom description on the Released products page

or purchase order lines.

To work with customs descriptions, go to Landed cost >

Shipping information setup > Customs description.

There, you can view, open, create, and delete records for custom descriptions.

¨ Auto

Costs Setup

You can use the auto costs page

to set up cost rules for various cost areas (such as voyages, shipping

containers, folios, purchase orders, items, or transfer order lines). Based on

the rules, and the fields that users select when they create records for one of

the cost areas, the system calculates the costs and automatically adds them.

Therefore, users do not have to manually add the costs.

To work with auto costs, go to Landed cost >

Costing setup > Auto costs.

¨ Costing

parameter values setup

When you set up the landed cost module,

you can define several sets of common values and related settings per value.

These values will then be available when you select specific types of costing

parameter values in other parts of the app.

We need to do some setup on the costing

parameter page which is given below

§

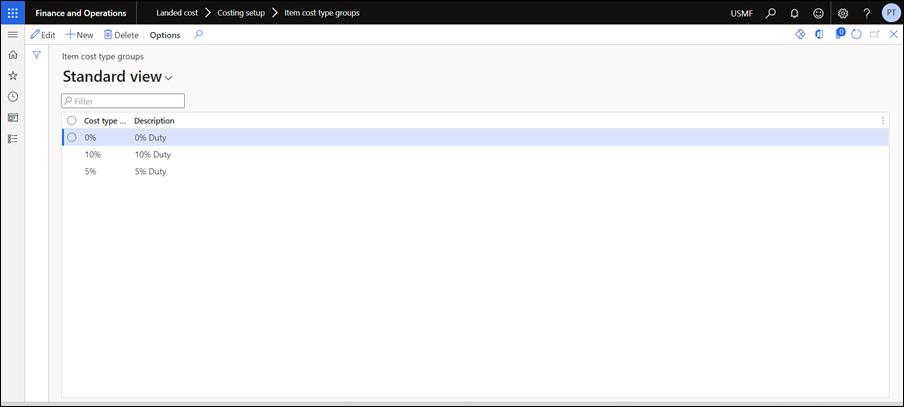

Set up cost-type codes

§

Vendor cost type group

§

Item cost type group

§

Transfer order cost type group

§

Cost templates

§

Volumetric divisors

¨ Landed

cost procurement and sourcing parameters setup

The procurement and sourcing

parameters page have a few settings that are especially relevant

when you use the Landed cost module. Use the update order

lines dialog box that is opened from the procurement and

sourcing parameters page to specify whether purchase order lines should

automatically be updated when changes are made on the purchase order header.

6.

End-to-end process: -

7.

Business scenarios: -

· Scenario 1: Purchase order with one shipment

Supplier 1 costs 50$ per product, Supplier 1 charges a fixed fee of

$500 freight for international shipment, and the significant duty rate is 5%.

Purchase order created with 50 quantities.

Cost from Supplier 1: $2500 + $500 freight+$ 5 freight + ($2,500

*.50 Duty+10) = $2,500 + 505 + 135 = $3,140

· Scenario

2: Purchase order with multiple shipments

Supplier 2 costs 70$ per product, and Supplier 2 charges a fixed fee of

$500 freight for international shipment, and the duty rate is 5%.

Purchase order created with 60 quantities but the received quantity

in two containers 30pcs each.

Cost from Supplier 1 (Shipment 1): $2100 + $500 freight+$5

freight + ($2,100 *10% Duty+10) = $2,100 + 500+5 + 210+10 = $2,825

Cost from Supplier 1 (Shipment 2): $2100 + $500 freight+$5

freight + ($2,100 *10% Duty+10) = $2,100 + 500+5 + 210+10 = $2,825

· Scenario

3: Two Purchase orders with one shipment

The same item is purchased from two different vendors and the

quantity is delivered through multiple deliveries.

Purchase 10 units at the price of $100 Per unit.

Cost from Supplier 1 (PO1): $1000 + $500/6 freight+$ 100/6

freight + Duty $200/6 + ($1,000 *5%) + insurance $5000/6 = $1,000 + 83.33+16.67 + 833.33+33.33 +50= $2,016.67

Purchase 100 units at the price of $150 Per unit with a

different vendor but the same product. The delivery of goods is split 50 units

each container.

Cost from Supplier 2 (PO2): $7500 + $500-83.33(PO1) freight +

$100-16.67(PO1) freight + Duty$200-33.33 (PO1) + ($7500*5%) + Insurance

$5000-833.33 (PO1) = $7,500 +416.67+83.33+166.67+375+ 4,166.67 = $12,708.34

Another 50 quantities are received in another container.

Cost from Supplier 2: $7500 + $500freight+$ 100 freight +

Duty$200+ ($7500 *5%) +5000 = $7,500 + 500+100+200+375+ 5000 = $13,675

· Scenario

4: In-transit orders

The item is purchased from the vendors before receiving the

item we process the invoice.

Purchase 100 units at the price of $30 Per unit.

Cost from Supplier 1: $3000 + $500 freight + ($3,000 *5% fuel) = $3,000 + $500+$150 = $3,650

· Scenario

5: Over delivery (Goods are received over against the purchase order)

Supplier 1 costs 50$ per product1, Supplier 1 charges a fixed

fee of $500 freight for international shipment, and the significant fuel rate

is 5%. Purchase order created with 30 pieces. At the time of shipping, the

vendor shipped 27 pieces of that product. The system will automatically create

the purchase order for over 2 pieces.

Purchase 25 units at the price of $50 Per unit.

Cost from Supplier 1: $1250 + $500 freight + ($1250 *5% fuel)

= $1250 + $500+$62.50 = $1812.50

· Scenario

6: Under delivery (Goods are received less than against the purchase order)

Supplier 1 costs 60$ per product1, Supplier 1 charges a fixed

fee of $500 freight for international shipment, and the significant fuel rate

is 5%. Purchase order created with 30 pieces. At the time of shipping, the

vendor shipped 25 pieces of that product. we get less than 5 pieces from the ordered

quantity. We can create a movement journal for the 5 quantities.

Purchase order created for 30 quantities.

Cost from Supplier 1: $1800 + $500 freight + ($1800 *5% fuel)

= $1800 + $500+$90 = $2,390

8.

Transfer orders: -

·

Landed costs are available for

accruing transportation costs for transfer orders between warehouses in a single

legal entity/company F&O.

·

Transfer orders work similarly to

what was described in the purchase order example above however, they do not

have the concept of a goods-in-transit order (Since there is no ownership

change).

·

Transfer orders do work in the

warehouses with “Advance warehousing” enabled.

¨

Ensure you ship the container via the

shipment confirmation button the shipment form vs. the voyages form.

¨

You will have an outbound load and

shipment along with the associated inbound voyages.

· Business

scenarios: -

Scenario1:

- The item is

transferred from one warehouse (W001) to another warehouse (W003) in the same

legal entity by shipping container.

The

landed cost will affect the item.

Transferred qty is 10 units at the

price of $96.68 Per unit. The freight is $ 500.

Cost: - $966.68 + $500freight=

$1,466.68

Scenario2:

- The item is

transferred from one warehouse (W001) to another warehouse (W003) in the same

legal entity by shipping container.

The

landed cost will affect the item.

Transferred qty is 20 units at the

price of $160.28 Per unit. The freight is $ 500, duty is $10.

Cost: - $20*160.28+ $500freight + $

10 duty= $3,722.54

9.

Landed cost Vs Transportation management

system: -

Microsoft

Dynamics 365 Supply Chain Management provides two different modules for working

with transportation: Transportation management (TMS)

and Landed cost.

There

are some differences between both modules.

· Voyages

in landed cost Vs. inbound loads in TMS

¨

You can use TMS inbound and outbound

operations. Although Landed cost provides almost the same functionality as TMS for

inbound operation, it also adds some functionality. Therefore, you might want

to consider using TMS for outbound operations and Landed costs for inbound

operations.

¨

In general, we don’t recommend that

you use both modules together for inbound operations.

§

If you do use the two modules

together, you must not share documents with them. For example, don’t use the same

purchase order for both a load in TMS and a voyage in Landed cost.

§

You must ensure that you don’t set up

the system to create inbound loads automatically. If items from purchase orders

are included in a voyage, they can’t be handled as part of a load.

· Landed

Cost Vs. TMS- Key Considerations

¨

TMS and Landed cost don’t share

reference data for entities such as cost setup, journeys, and legs. If you use

both modules, you must re-create the unshared reference data.

¨

Landed cost doesn’t provide an ASN

for the electronic receipt of goods. Additionally, it doesn’t support warehouse

management mobile app flows that processing load receiving, license plate receiving,

or mixed license plate receiving.

¨

Landed cost provides only limited

support for rate shopping by the vendor. Although you can enter freight

forwarder values, landed cost doesn’t- compare them across multiple vendors.

¨

TMS supports the creation of freight

charges that are connected to transfers. Although these charges can be viewed

from the transfer order, the landed cost isn’t added to the item cost. Freight

reconciliation is supported through the creation of a freight bill that is

based on these charges. This freight bill is then matched against a vendor

freight invoice.

No comments:

Post a Comment